Night vision goggles save lives in aviation. But even tiny spots or defects can turn these life-saving tools into safety hazards. Night vision blemishes are dark spots, bright artifacts, or distortions that appear in your image intensifier tube. They block your view and hide critical flight information.

This guide shows you how to prevent tube blemishes and keep your night vision devices working at peak performance. Clean optics mean safer flights.

What Are Night Vision Blemishes?

Not all spots seen in night vision goggles are equal; understanding factory spots versus blemishes safeguards overall image quality.

Factory spots form during production. Even with atomic layer deposition and strict quality control measures, tiny imperfections or dust can leave dark spots on the phosphor screen.

Industry standards rely on the spot zone chart test. Zone 1, the visual center, allows almost no flaws, while Zones 2 and 3 tolerate slightly more.

Military standard spot spec tolerances are toughest. Aviation tubes demand near-perfect image intensifier tube clarity, forbidding any spots exceeding a 0.003-inch spot size inside Zone 1.

Blemishes are post-factory defects. Shock damage, laser damage, recoil damage, or misuse create artifacts and lasting tube damage that erode contrast and resolution.

Regular inspection catches new issues early. Proper cleaning procedures and storage recommendations protect the microchannel plate and photocathode, preserving light sensitivity and extending device lifespan despite inevitable manufacturing challenges.

How Blemishes Impact Flight Safety

Clear vision keeps pilots alive. Any imperfection in your night vision devices can hide obstacles, aircraft lights, or terrain features. A large dark spot could block an oncoming aircraft beacon. Distortion affects depth perception and contrast recognition.

Aviation night vision goggles must meet the highest industry standards. Military specifications require virtually spotless tubes for flight operations. Pilots train to spot operational defects during pre-flight checks. Edge distortion, vignetting, or large blemishes make the device unfit for flight.

Clean image intensifier tubes provide better situational awareness. Modern Gen 3 devices use gallium arsenide photocathode materials for superior light sensitivity and resolution. The manufacturing precision creates uniformity across the entire viewing area.

Poor image quality from blemishes or artifacts forces pilots to work harder to interpret what they see. This mental strain increases fatigue and reduces reaction time when split-second decisions matter most.

Common Causes of NVG Damage

Understanding how blemishes form helps you prevent them. Damage typically comes from two sources: excessive light and physical trauma.

Light-Induced Damage

Photonic damage happens fast. Night vision devices amplify tiny amounts of light thousands of times. Sudden bright light overwhelms the delicate photocathode and phosphor screen components.

Looking at artificial lights or sunlight through active goggles burns permanent marks into your tube. Laser pointers create instant spot damage. Even moderate light exposure over time can ghost images into the microchannel plate structure.

Modern devices include automatic brightness control and gated power supplies. These features help but cannot prevent all damage from extreme light exposure.

Physical Trauma

Image intensifier tubes contain microscopic structures that break easily. The microchannel plate is essentially millions of tiny glass channels amplifying electrons. Shock damage disrupts these delicate components.

Recoil damage from weapons mounting affects many users. High-caliber firearms create enough force to jar internal tube layers. Shock damage from dropping or impacts causes similar problems.

When internal components collide, you get dark blemishes or bright emission points where electrical connections fail. The tube’s precision alignment gets “bent out of shape” permanently.

Prevention Best Practices

Proper care prevents most blemish damage. These practices extend your equipment life and maintain peak performance.

Handle With Care

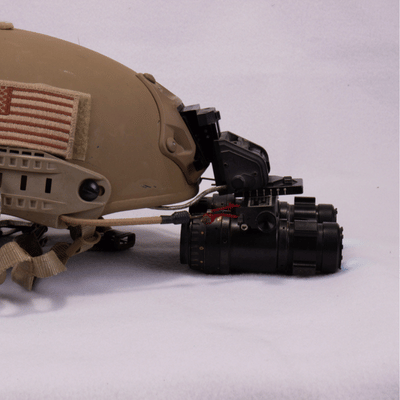

Treat night vision goggles like the precision instruments they are. Use secure helmet mounts that lock properly during flight operations. Store devices in padded cases when not mounted.

Avoid weapon mounting unless your device is specifically rated for recoil forces. Aircraft vibration requires cushioned mounting points to prevent gradual damage over time.

Modern devices meet MIL-STD-810 durability standards but “rugged” does not mean “invincible.” Gentle handling prevents most physical damage.

Protect Against Light

Light discipline saves tubes. Never expose active goggles to daylight or bright artificial lights. Always use lens caps or daylight filters in bright conditions.

Store devices in dark cases during daytime operations. Use opaque covers that block all light completely. Standard rubber lens covers work well for this protection.

Laser threats pose special risks to pilots. Handheld laser pointers from the ground can permanently burn spots through your goggles. Consider laser interference filters if available for your specific device model.

Activate automatic brightness control features if your goggles have them. Auto-gating rapidly dims the tube when detecting sudden bright light.

Proper Storage Methods

Storage conditions affect long-term tube health. Keep devices in dedicated protective cases that shield from impacts, dust, and light. Choose cool, dry locations with stable temperatures.

Extreme heat degrades components while cold conditions risk condensation damage. Never leave goggles on dashboards or in direct sunlight.

Remove batteries during extended storage periods. This prevents corrosion from battery leaks and accidental power-on incidents inside cases.

Regular Inspection Routines

Pre-flight checks catch problems early. Inspect your goggles before each flight operation. Look for new spots, edge glow, or flickering issues.

Test suspicious spots by covering the objective lens completely. Spots that remain visible with no light input indicate tube blemishes needing attention. Spots that disappear might be less serious artifacts.

Document blemish locations using clock positions and distance descriptions. Track changes over time to identify growing problems.

Cleaning Procedures

Clean lenses maintain optimal image quality and prevent dirt from masking tube conditions. Use proper optics cleaning tools and techniques.

Blow off particles with compressed air first. Use soft lens brushes or microfiber cloths with approved cleaning solutions. Never use harsh solvents or rough materials that scratch lens coatings.

Keep housing seals and filters in good condition. Check O-rings and purge systems regularly to maintain internal environmental stability.

Professional Maintenance

Aviation night vision devices require periodic professional inspections every 180 days per FAA guidelines. Certified technicians use specialized test equipment to measure performance metrics.

Quality checks include resolution testing, signal-to-noise measurements, and gain analysis. Technicians map blemishes and track performance trends over time.

Minor cosmetic spots within specifications need only documentation. Large blemishes in Zone 1 or those affecting critical vision may require tube replacement.

Check warranty coverage before repairs. Manufacturing defects often qualify for replacement while user-induced damage may not be covered.

Advanced Tube Technologies

Modern manufacturing challenges drive continuous improvements in night vision technology. Atomic layer deposition creates more uniform photocathode materials with better quantum efficiency.

Gallium arsenide photocathodes provide superior light sensitivity compared to older materials. Advanced quality control measures reduce factory defects during the image intensification process.

These manufacturing precision improvements result in cleaner tubes with fewer inherent imperfections. Better uniformity across the viewing area reduces distracting artifacts.

Maintenance Best Practices

Establish regular user maintenance practices beyond basic cleaning of dark spots and checking factory spots against spot spec tolerances and quantum efficiency logs. Monitor your devices for gradual changes in performance or new artifacts.

Storage recommendations include climate-controlled environments and proper case selection to maintain quantum efficiency. User maintenance practices should focus on preventing damage rather than attempting repairs.

Never disassemble image intensifier components. Internal repairs require specialized facilities and trained technicians with proper equipment.

Take Action for Safer Flights

Your night vision equipment is only as good as the care you give it. Start implementing these prevention practices immediately. Create pre-flight inspection checklists that include blemish checks for dark spots. Train your team on proper handling and storage procedures.

Don’t wait until damage occurs. Schedule professional inspections now and establish maintenance records for your devices. Clean equipment performs better and lasts longer.

Contact us today to assess your current equipment condition and establish a maintenance schedule. Your safety depends on clear vision when it matters most.